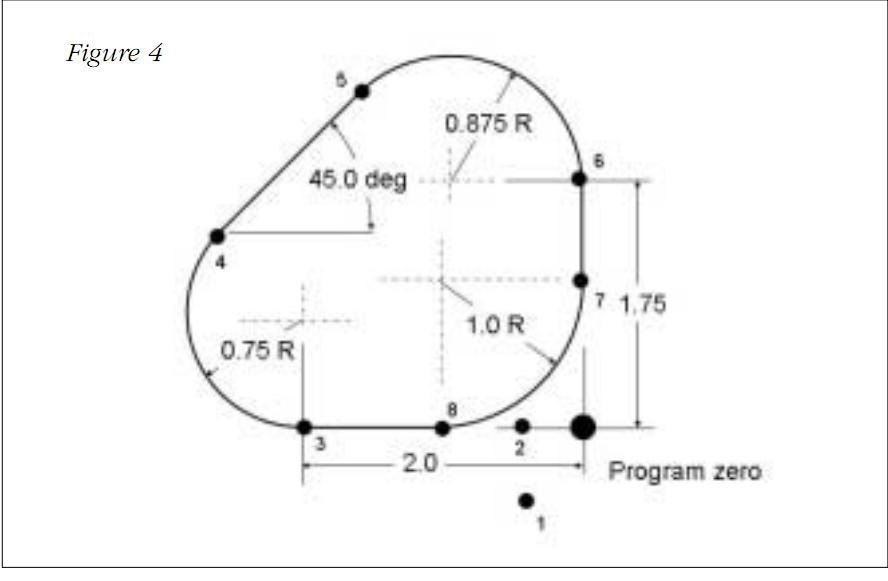

O0001 (Program number)

N005 T01 M06 (Place 1.0 inch milling

cutter in spindle)

N010 G90 G54 S700 M03 T02 (Select

abs. mode, coordinate system, start

spindle, and get the next tool ready)

N015 G00 X-0.5 Y-0.6 (Rapid to point

1)

N020 G43 H01 Z-0.6 (Rapid to work

surface in Z)

N025 G41 G01 D31 Y0 F5.0 (Instate

cutter comp to point 2)

N030 G16 X-2.0 Y0.75 A270.0 Q0.75

(Instate polar coordinates, feed to

point 3)

N040 G02 A135.0 R0.75 (Circular

move to point 4)

N045 G01 X-0.875 Y1.75 A135.0

Q0.875 (Feed to point 5)

N050 G02 A0 R0.875 (Circular move to

point 6)

N055 G01 X-1.0 Y1.0 A0 Q1.0 (Feed to

point 7)

N060 G02 A270.0 R1.0 (Circular move

to point 8...)

N065 G00 G16 Z0.1 (Rapid out in Z,

cancel polar coordinates)

N070 G40 (Cancel cutter comp.)

N075 G91 G28 Z0 M19 (Return to tool

change position, orient spindle)

N080 M01 (Optional stop)

(mam w robocie dwie maszyny na fanucu ale żadna tego programu nie kupuje)

potrzebuje informacji na temat jak przybierać np 1 stopień po określonym łuku lub jak wykonać pełne koło